Dutch Automation Leader Building Mega Freezer in Canada

One of the world’s most advanced cold storage and logistics company is coming to Canada, planning to disrupt the market for 3PL cold chain services.

The Netherlands-based company NewCold, rapidly expanding with 15 facilities worldwide across North America, Europe, and Australia, is investing $1.45 Billion in Guelph, Ontario, to erect a 150-foot-high freezer facility. Once completed, this facility will stand as Canada's largest cold storage unit. Equipped with cutting-edge automated storage and retrieval systems, it will efficiently handle food products in sub-zero conditions for clients across North America, Europe, and Australia.

This development promises healthy competition in Canada's cold storage sector, traditionally dominated by a near-monopoly. NewCold's disruptive impact is well-known internationally, leveraging its exceptional engineering, logistics, and operational efficiencies to offer significantly lower storage rates.

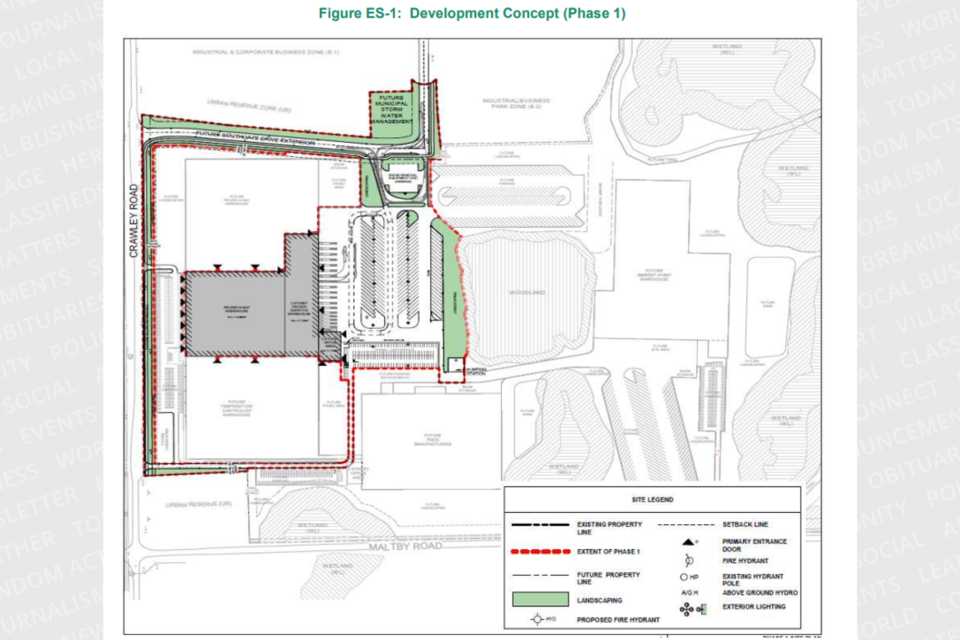

The plan outlines a 46-meter frozen high-bay warehouse covering 14,683 square meters (160,000 square feet), alongside a two-story dispatch warehouse. Despite local environmental concerns and minor procedural issues, the Ontario Land Tribunal's decision on April 5th deems Industrial Equities Guelph Corporation's application complete, clearing the path for city council consideration.

About NewCold Advanced Cold Storage Logistics

NewCold stands out in the industry with its unparalleled focus on automation. The company has established itself as specialists in developing high-tech solutions, including best-in-class cold chain logistics software. This highly specialized expertise has enabled NewCold to pioneer some of the largest and most highly automated facilities globally. NewCold delivers innovation at every stage of the supply chain – from design through to development and operation, providing leading service levels and continuous improvement programs that keep customers progressing.

Since its inception in 2012, NewCold has grown into one of the world's largest and most advanced automated warehouse and cold chain logistics companies. The company boasts a rapidly expanding global presence, with its Innovation & Support Center located within the head office in Breda, the Netherlands. A pioneer in developing and operating frozen automated warehouses, NewCold offers significant footprint, labor, and energy reduction with increased food safety.

NewCold’s global network spans across three continents, encompassing 15 locations and offering over 1,187,000 pallet positions. Its transport fleet comprises over 200 trucks and 300 trailers, supported by a global team of over 2,000 employees.

Former customers, including Froneri (formerly known as R&R Ice Cream), McCain, and Unilever, have chosen NewCold for new projects. With a big vision and even bigger ambitions, NewCold, supported by a strong leadership team and dedicated employees, has expanded its operations to the United States and Australia.

NewCold operates as an integrated service provider for cold chain logistics, based in the Netherlands. It operates a European network of large-scale automated cold stores and refrigerated transport, serving frozen food producers in France, Germany, the United Kingdom, and Poland. Furthermore, NewCold is expanding its global operations with facilities in Australia and plans for more in the US.

NewCold stands out as a very unique company with the engineering prowess and knowhow to fast track and operate very complex cold store projects involving automation, robotics, and highly sophisticated software controls.

Continuously seeking the world’s best solutions in refrigeration and thermal scopes, NewCold equips its very tall automated storage freezers, which can usually store approximately 100,000 pallet positions, with state-of-the-art technology. Their facilities utilize automated storage and retrieval systems (ASRS) to automatically move and store products in the ‘dark’ high-bay warehouse, maintaining optimal conditions with all facility areas cooled down to sub-zero temperatures. Additionally, several of their facilities feature low-oxygen fire suppression systems.

What is a Fully Automated High Bay Warehouse?

The automated high bay warehouse is the all-rounder for heavy and medium loads. Controlled by modern software, the storage and retrieval process takes place completely independently – making it highly dynamic and very safe. Its performance extends to round-the-clock operation.

The automated high bay warehouse mainly consists of pallet racks, which are approx. 12 to 45 m high and can be made of steel or wood. In the aisles between the racks, storage and retrieval machines (SRM) or shuttle vehicles are used to pick up or place the palletized goods.

The automated high-bay warehouse has a ultrad compact design, accommodates pallets up to a total weight of 3,500 kg each, single or multiple deep, and makes very good use of storage space. The technology is robust and allows for ambient temperatures from -30 °C to +45 °C. This makes it suitable for use in a wide range of industries.

Guaranteed: Our Warehouse Automation Systems are designed to operate 20% faster and 20% more cost-effectively than your current leading solution. If our system fails to meet these benchmarks, we will take it back at no cost to you.