Lee Valley Tools Online Hub Emerges with Automated Facility in Ottawa

Lee Valley Tools has launched a new automated fulfillment center in West Ottawa that relies on automation and technology to increase efficiency and allow more room for manufacturing operations.

Founded 45 years ago by former public servant Leonard Lee as a mail-order business that sold do-it-yourself stove-making kits, Lee Valley Tools has evolved into a sales and manufacturing powerhouse with 18 retail stores in seven provinces, 1,000 employees and annual sales well in excess of $100 million.

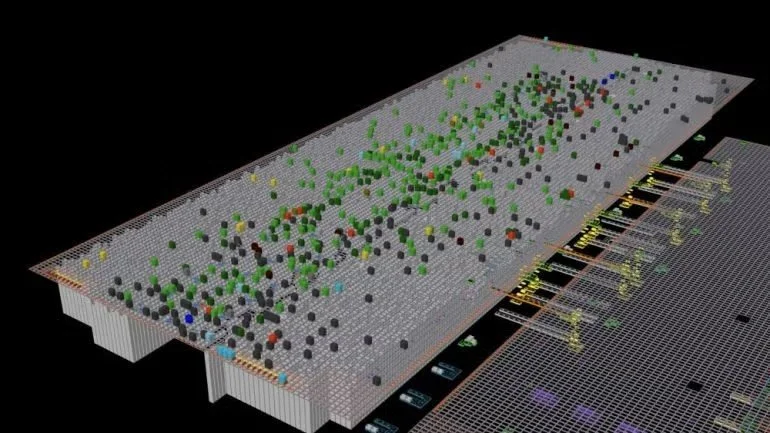

The new facility is operating out of Lee Valley’s 150,000-square-foot distribution warehouse in West Ottawa, which processes all of Lee Valley’s global inbound trade for distribution to stores and customers. With the addition of new automation and technology, the new high density cube storage system consolidates 36,000 square feet of picking locations into 6,000 square feet, thereby freeing up space to expand manufacturing at the facility.

The new automated cube system called Auto-Store features 42 red robots that retrieve products for warehouse operators from the 18,000 tote locations storing Lee Valley products. The automated ASRS workflows have more than doubled the picking speed to 250 lines per hour at each workstation.

“By investing in manufacturing and automation, we are strengthening our foundation and helping employees with tasks that involve undesirable work like repetitive lifting and walking all day,” said Lee Valley COO Jason Tasse in a news release. “The more efficient we can make our operations, the more flexibility we have to adapt to disruptions that may occur during seasonal hiring periods and can scale appropriately as needed.”

Lee Valley has more than 200 employees based in the National Capital Region. “This is our hub, nationally and globally,” said Tasse.

Tasse described the challenging AutoStore project as “equivalent to changing the engine in a moving car.”

“And, quite frankly, we pulled it off as seamlessly as we did because of the calibre of the employees and the dedication and care that they invest in Lee Valley Tools.”

The investment in the automated systems, “speaks volumes to the courage and boldness of our company, as we continue to respond to the ever-changing economic landscape,” Tasse added.