Symbotic Unveils Next-Generation Warehouse Automation System

Warehouse automation leader Symbotic Inc. announced today the release of its next-generation storage system, claiming dramatic improvements in space utilization, deployment speed, and throughput performance.

While Symbotic has long been known for its advanced robotic case-handling platform used by retail giants like Walmart and Target, this new development signals a clear step forward in solving one of the most pressing challenges in warehouse automation today: space and deployment efficiency.

The warehouse automation industry is reaching a critical inflection point. As urban land costs rise and brownfield retrofits outpace greenfield builds, the need for ultra-high-density systems and rapid deployment capabilities is becoming paramount.

Symbotic’s new storage structure responds directly to these demands. According to their announcement, the system can:

Reduce a customer’s storage footprint by up to 40%

Enable shorter and faster robotic case delivery trips

Cut on-site assembly complexity by over 90%

Minimize floor leveling costs via a built-in adjustment mechanism

Support both retrofits and greenfield sites

Technical Innovations at a Glance

1. Ultra-High-Density Design

The redesigned storage structure accommodates a wider range of case sizes with a modular shelf system. This unlocks significant densification—either to store more in the same space or maintain existing capacity with a smaller footprint.

2. Faster Case Handling

With bots traveling shorter distances between pick and drop locations, Symbotic expects improved throughput and energy efficiency per case handled.

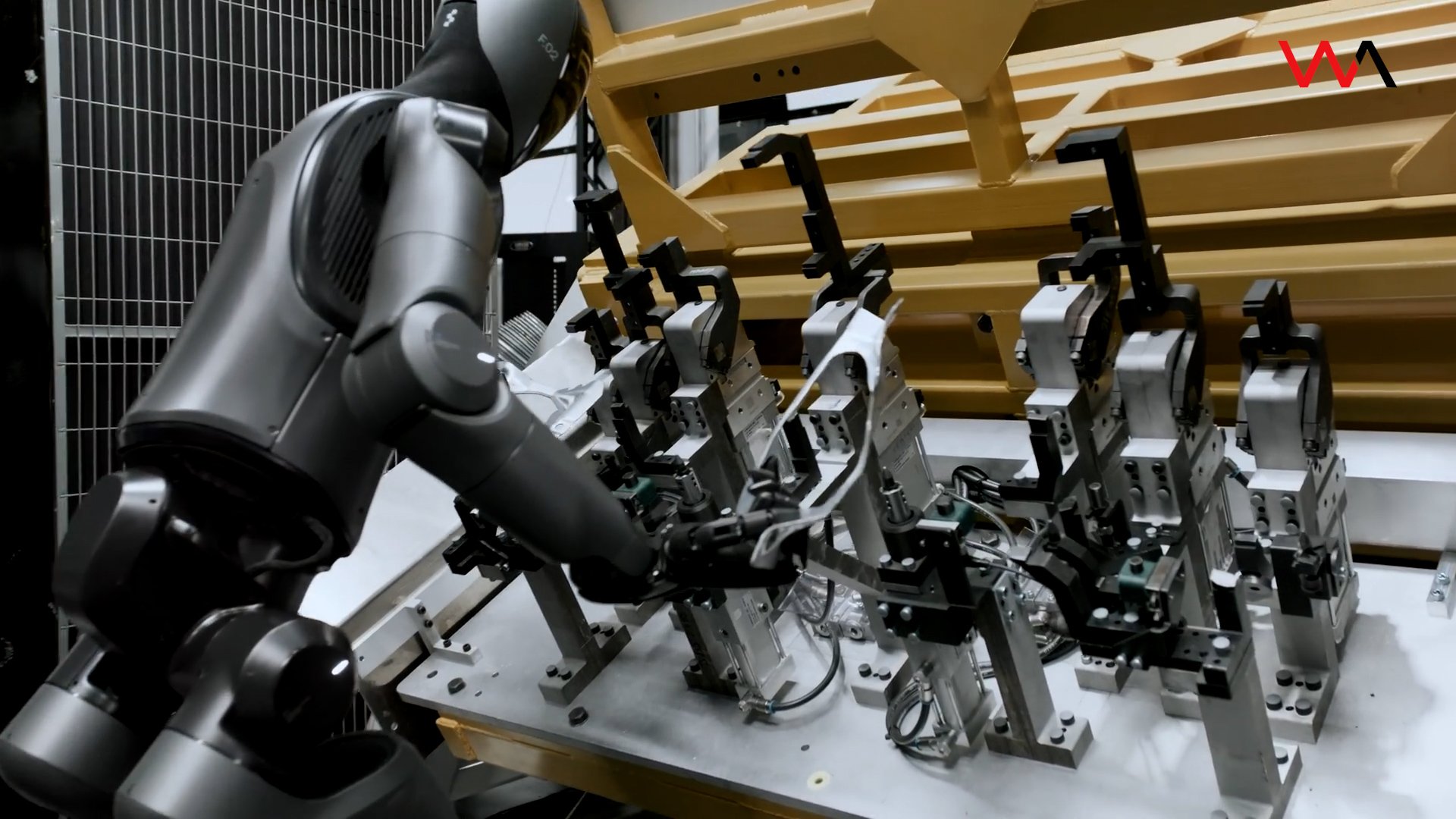

3. Pre-Assembled Subcomponents

Pre-fabricated structures reduce the number of on-site parts by 90%, allowing for faster implementation and earlier go-live timelines.

4. Seismic & Safety Engineering

Integrated fire suppression and seismic strengthening options allow Symbotic to meet diverse building code requirements globally.

5. Built-In Leveling System

One of the more overlooked yet costly steps in automation is preparing the floor. Symbotic’s leveling approach may help customers avoid extensive concrete work—especially valuable in older facilities.

Critical Implications

This announcement reinforces Symbotic’s shift from being viewed strictly as a “case robot company” to a full-stack warehouse infrastructure provider. By expanding their portfolio to include physical storage infrastructure, they are increasingly offering an end-to-end system designed to accelerate time to value for customers.

In our own conversations with enterprise buyers across North America and Europe, two recurring challenges often emerge:

Fitting automation into constrained footprints

Reducing long deployment timelines and construction costs

Symbotic’s new storage system appears purpose-built to address both.

Initial Conclusions

This release is more than just a hardware upgrade. It represents a broader shift toward modular, rapidly deployable warehouse systems that don’t require tearing down buildings or waiting a year to go live.

We’re particularly interested in the retrofit potential, especially for customers operating legacy infrastructure where floor preparation and height constraints have traditionally slowed down automation rollouts.

We’ll be watching closely to see how Symbotic’s system performs in the field, what real-world density and throughput gains are reported, and how it stacks up against other mixed-case picking systems such as Witron and Swisslog.

Want to Compare the Leading High-Density ASRS Systems?

Considering automation, robotics, or software upgrades like WMS or warehouse execution systems? Our advisory team connects you with supply chain and engineering experts who have designed and integrated world-class automation at Amazon, Walmart, GXO, DHL, and other leaders. Whether you’re evaluating humanoids, AMRs, piece-picking systems, or integrating software into ASRS and fulfillment workflows, we provide vendor-agnostic guidance and practical roadmaps for your digital transformation. Connect with us by clicking the button below to explore your next steps.

If your organization is evaluating automation projects and struggling to decide between vendors such as Symbotic, AutoStore, Exotec, or Geek+, we’ve created a free, vendor-agnostic ASRS Comparison Guide to help.

Contact us at solutionhub@warehouseautomation.ca to receive a complimentary copy, or schedule a call with our engineering team.

A frenzy of investment has created a crowd of new human-like designs.