Walmart Goes All In on Automated Packaging

Walmart’s rollout underscores what industry leaders like Amazon have already shown — automation is the backbone of modern fulfillment.

The retail and e-commerce landscape is evolving rapidly, and automation is at the heart of that transformation. Walmart is now moving ahead with a major rollout of automated packaging machines across its next-generation fulfillment centers — a move that signals the technology’s maturity and undeniable value.

While this is a new step for Walmart, Amazon has been integrating similar machines for several years across its global network of fulfillment centers, quietly proving their efficiency, scalability, and impact. Walmart’s decision marks a significant shift and a clear sign that the rest of the retail industry is heading the same way.

From Pilot to Full-Scale Deployment

After successful trials at its Indiana facility, Walmart is now deploying automated packaging technology across multiple centers in Pennsylvania, Illinois, Texas, and California.

This isn’t a small step. It represents a strategic pivot from testing automation to embedding it into the operational core of their fulfillment strategy. The message is clear: automation is no longer experimental — it’s a must-have.

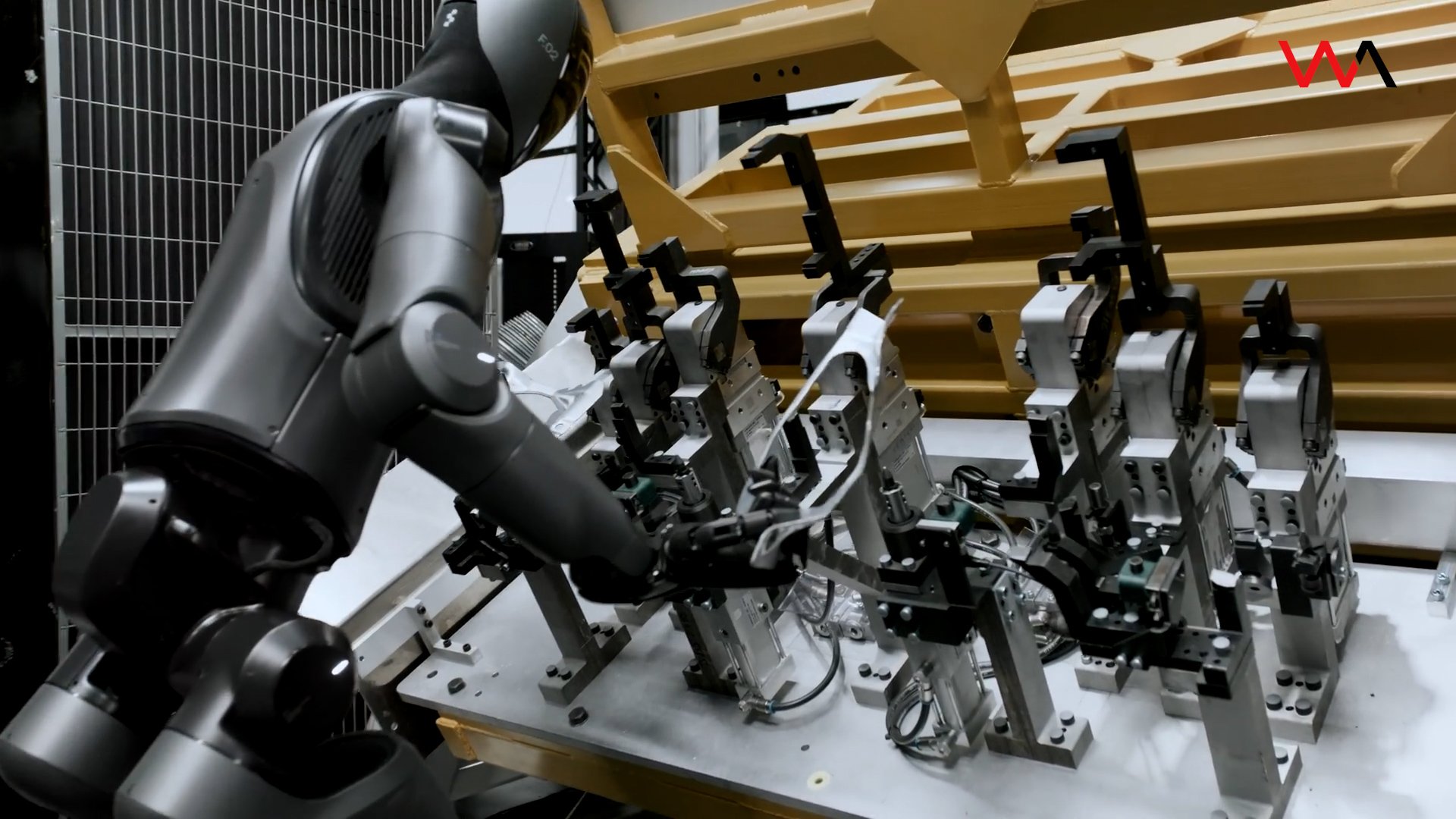

The Technology Driving the Change

Automated packaging machines use AI-powered machine vision and robotics to handle one of the most repetitive and labor-intensive parts of the fulfillment process. These systems:

Measure each box in real time, determining the exact amount of space to fill.

Dispense the precise amount of filler, eliminating unnecessary material and reducing damage during transit.

Automatically close and seal boxes, speeding up throughput and improving consistency.

The result is a faster, cleaner, and more efficient packaging process — reducing waste, improving shipping accuracy, and enabling associates to focus on higher-value tasks.

Amazon Set the Standard — Walmart Is Catching Up

For years, Amazon has quietly led the way, deploying these machines in fulfillment centers worldwide. Their success has demonstrated that automated packaging scales efficiently, reduces operational costs, and supports sustainability initiatives.

Walmart’s decision to embrace this technology shows that the industry is recognizing automation as essential infrastructure, not a future concept. Companies that delay this shift risk falling behind as their competitors streamline operations and enhance customer satisfaction.

Why Other Companies Should Take Note

The advantages of adopting automated packaging systems are now clear and proven:

Speed to customer: Faster throughput leads to shorter delivery times.

Cost savings: Less waste and optimized labor reduce operational expenses.

Sustainability: Smarter packaging minimizes material usage and environmental impact.

Employee empowerment: Associates can focus on higher-value work instead of repetitive manual tasks.

Mid-sized retailers, e-commerce brands, and 3PLs should view Walmart’s move as a signal: automation is no longer just for the largest players.

The Bottom Line

Walmart’s rollout underscores what industry leaders like Amazon have already shown — automation is the backbone of modern fulfillment. This shift isn’t just about technology; it’s about building faster, smarter, and greener operations that meet today’s rising customer expectations.

For businesses still on the fence, the question is no longer if they should integrate automated packaging — it’s how quickly they can make it happen.

Would you like me to make this version more technical and metrics-driven, showing potential throughput or cost-reduction benchmarks that Amazon and Walmart could be achieving?