Companies Brought in Robots. Now They Need Human ‘Robot Wranglers’

Lost and confused automation create work for people. Robots wander off ‘like a child’ and irritate workers by following them or ‘trying to get under their desk.’

Article By Liz Young | Photographs by Elijah Nouvelage for The Wall Street Journal (Jan. 30, 2024)

Caroline Rutenberg got an alert one day that one of her charges needed help at the Amazon.com warehouse where she works in Windsor, Conn.

Rutenberg walked across the warehouse floor and found the crew member covered in white paint and refusing to move after an accidental spill.

Rutenberg took a cloth and gently wiped off the worker’s eyes, getting a glassy, expressionless stare in return. But it’s not like she expected a “thank you”—her underling is a robot, a squat machine on wheels that looks like a Roomba vacuum with a conveyor belt on top.

Androids of various shapes, sizes and functions are now employed doing everything from autonomously ferrying goods around warehouses to delivering food on college campuses. About 21% of warehouses used some form of robotics in 2023, up from 15% in 2018, according to research firm Interact Analysis.

But far from replacing humans entirely, companies are finding automatons need a little hand-holding to learn how to function in the real world.

Samples dusts off the cameras used for autonomous guidance and obstacle avoidance.

“Everyone knows the drive number of it, and people are like, ‘Oh s—, not again. It’s him again,’” Rutenberg said. “We kind of give them a little personality.”

Blinky couldn’t be reached for comment.

Scott Samples is known as the “robot wrangler” at an appliance-manufacturing plant run by Roper, a subsidiary of GE Appliances, in LaFayette, Ga. Samples is the person factory workers call when a robot wanders off its designated path.

“I’ll either get a text with a picture or I’ll get a phone call and they’ll say, ‘Hey, your robot’s over here on such and such line, can you come get it?” he said.

Two of the plant’s many automated robotic vehicles pose for a photo with Samples. He is the contact person for any ‘meandering’ automation.

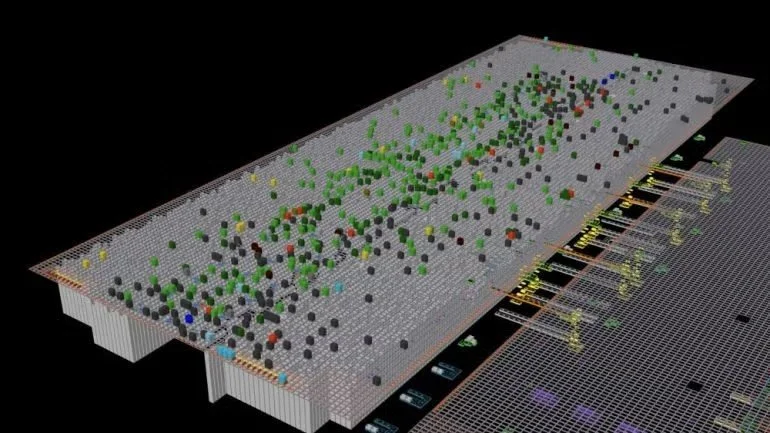

The 25 robots at Roper—which come in a variety of shapes, including one that Samples says looks like “putting wheels on a pumpkin”—work on tasks such as delivering parts and materials to the assembly line and moving finished products. They are programmed to follow a digital map of the facility and to use camera vision and light detection and ranging technology to stay on course. But occasionally they stray out of bounds, where they can no longer locate themselves on the digital map, shut down and wait for help.

“We’ve found them on a receiving dock, just lost like a child in the park,” Samples said. Other times the automatons are “over by somebody’s desk or trying to get under their desk,” he said.

When Samples gets a call about a robot wandering off, he pulls up that particular bot on his computer and looks out of the cameras and sensors attached to the device to try to figure out where the android is within the 1.4 million-square-foot facility. He then goes out, manually finds the robot and guides it back inside its boundaries.

Samples said the facility’s human workers name the robots everything from Herbie to Wonder Woman, and they generally get along with their automated counterparts just fine. But sometimes there are standoffs between the humans and the machines.

A screen displays a message on a robot at the factory.

Sample points out a report on JOHNNY5, named after the robot in the movie ‘Short Circuit.’

The robots “make a decision if something’s in the way, they’ll go around it, but so will a person,” he said. That can lead to the robot and a person both trying to move out of each other’s way at the same time but repeatedly crossing into one another’s paths.

That’s when workers will tell Samples, “This thing is following me and will not let me by,” he said. “They don’t understand the technical aspect behind the scenes of why it’s behaving the way it is.”

The nascent field of robot wrangling is an attempt to bridge the gap between the warehouses of the past and the automated facilities of the future, as human workers clock in besides robots that can lift items, carry boxes and package e-commerce orders.

Robot wranglers say part of their job is to help employees learn how to work with the robots, and how to see them as a help rather than a hindrance or a threat to their careers.

A robot rolls through the factory. Sometimes there is friction between man and machine.

Sean Cusack, a robot engineer in Oakland, Calif., said conveying that message often isn’t very hard. “People envision robots as these completely intelligent, Terminator-level things,” he said. In reality, “they’re pretty silly,” he said.

Cusack worked on the construction of the Lucas Museum of Narrative Art in Los Angeles, overseeing robots responsible for sanding fiberglass.

One weekend when Cusack was working overtime, he set up a robot to sand the material, then retreated to a nearby room to watch. But as the robot began moving, Cusack realized he had forgotten to set a critical control. The bot was on an unalterable path directly into an expensive fiberglass panel.

The robot slowly crawled forward until it “put in a giant circular hole in the side of the panel,” he said. He had to explain to his team the hundreds of thousands of dollars worth of damage was his fault for not properly instructing the bot.

Jaci Story says the robots can have a mind of their own. The operations lead at San Francisco-based Starship Technologies works with a fleet of robots on the University of Tennessee campus, where the white boxes on wheels roll around delivering students items from burgers and fries to coffee. The robots are outfitted with speakers that announce deliveries and play music.

One morning, Story was lifting up a robot to plug in the charger underneath.

“As I was doing that, one of them just kind of made this crazy sounding scream. And then it said, ‘Whoa, whoa, we have rights you know,’” she said. “I just died laughing.”

Samples keeps tabs on another co-worker.

Just like with humans, the robot minders say some androids are less capable workers than others. At times the devices have to go on performance improvement plans to address problem behaviors.

Roper’s Samples said he currently has a robot with an undiagnosed issue that he and the team that handles engineering maintenance work can’t figure out. The device, named Apex 2, is calling for a part replacement, but even now that the part has been replaced, it still won’t run.

“Even the tech can’t figure out what’s wrong with it,” he said. “We’ve had to replace him with a spare for right now.”